BOX BEHNKEN DESIGN EXPERIMENTAL DATA

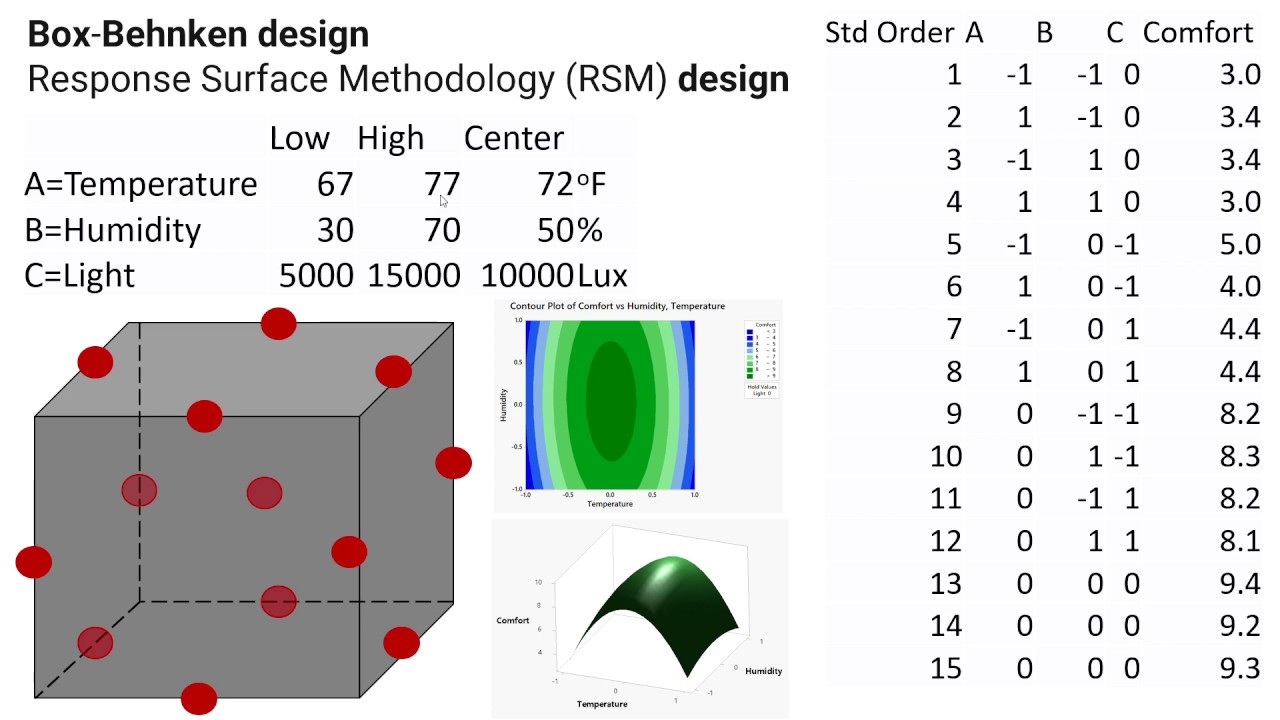

The matrix of Box-Behnken experimental design and experimental results were presented in Table 1. Up to 10 cash back Box-Behnken design.

Experimental Data Based On Box Behnken Design Plan For Example 1 16 Download Scientific Diagram

This exercise has become critical in this age of rapidly expanding the field of data science and associated statistical modeling and machine learningA well-planned DOE can give a researcher meaningful data set.

. The Box-Behnken design is rotatable or nearly so but it contains regions of poor prediction quality like the CCI. The Box-Behnken design uses the twelve middle edge nodes and three centre nodes to fit a. The optimum conditions.

The calculation of the data for the first-order response surface model revealed that R2 was 995 and that the model described most of the variance in the dependent variable phytic acid. Box-Behnken design is having the maximum efficiency for an experiment involving three factors and three levels. Therefore a Box-Behnken experimental design 18-19 was set up to check the effect of three variables.

These designs are rotatable or near rotatable and require 3 levels of each factor. C o 1539 mgL catalyst dosage 159 gL and solution pH 105. Use Create Response Surface Design Box-Behnken to create a designed experiment to model curvature in your data and identify factor settings that optimize the response.

Design of Experiment DOE is an important acti v ity for any scientist engineer or statistician planning to conduct experimental analysis. Its missing corners may be useful when the experimenter should avoid combined factor extremes. Box-Behnken designs are useful when you know you need to model curvature in your data because these designs usually have fewer runs than central composite designs with the same number of.

Box-Behnken Design is a useful tool for the optimization of the chromatographic analysis. Further the number of experiments conducted for this is much lesser compared to a central composite design. The maximum efficiency of ammonia removal was 80 at optimum conditions.

To fit a second-order regression model quadratic model the BBD only needs three levels for each factor Figure 15 rather than five levels in CCD Figure 14. The characterization results showed the suitable dispersion of ZnO over Oak charcoal. The BoxBehnken experimental design was used to provide data for modeling and the variables of model were Bond work index grinding time and ball diameter of mill.

Y f x1 x2 e In RSM the objective of DoE is the selection of the points where the response should be evaluated. 𝟑 𝟑 full factorial design 27 points Three one-third fractions of the 𝟑 𝟑 design. Compared to free cells 9434 the maximum Cd 2 removal efficiency reached 9865 for immobilized cells obtained via Box-Behnken design under optimized conditions comprising algal doses of 504 g L-1 and 496 g L-1 pH values of 506 and 684 and initial cadmium concentrations of 252 mg L-1 and 2619 mg L-1 respectively.

The BBD set a mid-level between the original low- and. This and the central composite techniques essentially suppress selected runs in an attempt to maintain the higher order surface definition. The proposed Box-Behnken design requires 15 runs of experiment for data acquisition and modeling the response surface.

Comparing the central composite design with 4 factors which has 31 observations a Box-Behnken design only includes 27 observations. In this design the treatment combinations are at the midpoints of edges of the process space and at the center. The goal of this study was to select the most significant factors that influenced the following parameters.

Accordingly effects of three process parameters pH load of PST PT gL and air flow rate AF Lh were. Requires 3 levels for each factor. Response surface methodology RSM of three factors extraction temperature extraction time and liquid solid ratio was employed to optimize the percentage yield of the polysaccharides.

BoxBehnken experimental design method was employed in order to evaluate the effect of process parameters and also optimize them. The application of Box-Behnken design to establish the optimum experimental condition of cake batter mixing is important because optimal mixing can ensure the dispersion of ingredients and the incorporation and retention of air efficiently. However RSM is an advantageous tool for solving the optimization problem of exact limitations.

Originally RSM was developed to model experimental responses Box and Draper 1987 and then migrated into the modelling of numerical experiments. For 5 factors the Box-Behnken would have 46 observations and a central composite would have 52 observations if you used a complete factorial but this is where the central composite also allows you to use a fractional factorial as. Dyeing temperature 10360C dyeing pressure 2423 MPa and dyeing time 6203 min.

The Box-Behnken method was preferred over central composite design CCD due to its high-quality prediction capability for the fewer combinations of experimental runs. Percentage of sodium chloride in the cement MgOKDP ratio and Waterbinder Wb ratio on the strength and the setting of the MKPC paste and to optimize a blended cement formula. Surface model and interpretation of the results were based on a 3k Box- Benhnken BBD experimental design with one replicate.

It could be seen that there was a considerable variation in. This property prevents a potential loss of data in those cases. BoxBehnken experimental design was used to optimize the experimental conditions.

The optimal process of dyeing was optimized by Box-Behnken Design experiment as following. Compared with the unmodified wool hank the rubbing fastness and the washing fastness of modified wool hank by protease were better and its color fastness met The National Standard GB18401-2003. Box-Behnken designs are used to generate higher order response surfaces using fewer required runs than a normal factorial technique see 10.

The Box-Behnken design is an independent quadratic design in that it does not contain an embedded factorial or fractional factorial design. Box-Behnken design which is experimental design for response surface methodology RSM is still considered more convenient and powerful than other designs. Box-Behnken Design BBD for the response surface methodology RSM is specially designed to fit a second-order model which is the primary interest in most RSM studies.

Specifically the optimization of polysaccharides was carried out using Box-Behnken statistical experimental design.

Box Behnken Designs For Optimizing Product Performance

Box Behnken Response Surface Methodology Rsm Design And Analysis Example Using Minitab Ms Excel Youtube

Box Behnken Design For Three Factors Download Scientific Diagram

Box Behnken Design Download Scientific Diagram

Geometric View Of A Three Factor Box Behnken Design Download Scientific Diagram

Box Behnken Design Of Experiments Download Table

Box Behnken Design Space For Three Factors 20 Download Scientific Diagram

Box Behnken Design And Full Factorial Design Matrix Representing Download Scientific Diagram

Experimental Conditions Of The Box Behnken Design In Coded And Natural Download Table

Experimental Design Layout Using Box Behnken Design Download Table

Example Of Box Behnken Design N 3 Download Scientific Diagram

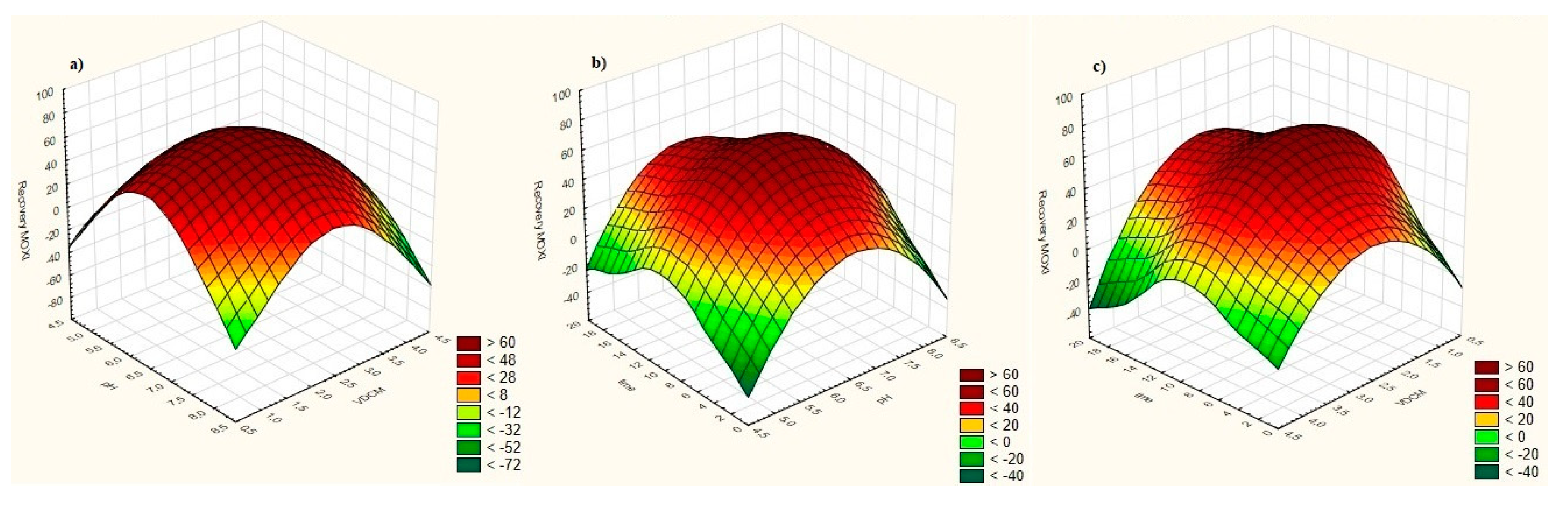

Processes Free Full Text Response Surface Methodology As A Useful Tool For Evaluation Of The Recovery Of The Fluoroquinolones From Plasma The Study On Applicability Of Box Behnken Design Central Composite Design And

Box Behnken Experimental Design Of 15 Runs And 3 Parameters Download Table

Box Behnken Design Bbd Experimental Design Table And Data Download Table

Box Behnken Design Matrix The Experimental And Predicted Values Of Download Table

%20Number.png)

0 Response to "BOX BEHNKEN DESIGN EXPERIMENTAL DATA"

Post a Comment